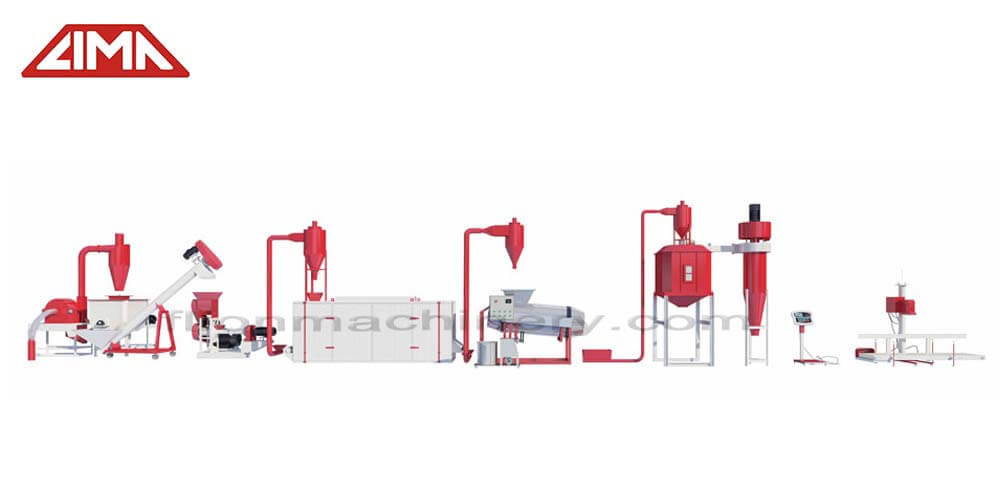

On December 15, 2020, the Fish feed production line was delivered to the customer at the port of Peru, including the fish feed mixer, fish feed pelletizer (dry type), fish feed dryer, etc.

Our fish feed pellet mill is well known in Nigeria, Uganda, India, Indonesia, and the USA, etc. On March 20, 2021, Mr. Sumit, a customer located in India, successfully purchased a 200kg/h floating fish feed machine.

Our fish feed pellet mill is well known in Nigeria, Uganda, India, Indonesia, and the USA, etc. On March 20, 2021, Mr. Sumit, a customer located in India, successfully purchased a 200kg/h floating fish feed machine. Mr. Sumit runs a large tilapia farm and has more than 10 farmers working with him. He started his fish farming business in ponds in 2000. After benefiting from it After benefiting from this, he decided to start the business and expanded his pond to a medium-sized fish farm. Until now, he has successfully expanded his fish production and become an expert in fish farming for local people. He has successfully expanded his fish production and has become a local expert in fish farming, and has gained a lot of pleasure in his daily life.

With the expansion of fish farms, the fish feed has become more and more important. On the one hand, consumers are more interested in nutritious and tasty fish, and on the other hand, large-scale fish ponds require more labor and material resources to produce fish feed, which prompted fish farmers to feed their fish with nutritionally balanced fish feed pellets.

This has prompted fish farmers to feed their fish with well-balanced fish feed pellets. For this reason, Mr. Sumit purchased a 200kg/h floating fish feed machine.

The floating fish feed machine plays an important role in the production of sinking and floating fish feed. The floating fish feed machine plays an important role in the sinking and floating fish feed production process. Firstly, the material is poured into the mixing chamber, water is added and a suitable one is added, then the feeding motor and the main motor are started, the rotating drive wheel drives it, which drives the rotation of the driven wheel, which drives the rotation of the feeding blade, which makes the raw material stir evenly, then stir evenly, the material under stirring is poured into the extruder system, due to the protective cover, then the cutting motor is started, which drives the rotation of the rollers, which makes the extrusion of the material purpose, so that the particles produced from the extrusion hole, extrusion in the role of small particles blade rotation will be cut out of the material, and finally from the discharge outlet to slide out of the machine.