How to adapt feed formulas and feed sizes to feeding conditions to help breed scientifically and save money.

Usually, feed production lines are in high demand by farmers on medium and large farms. Farms of this size have a high demand for feed and spend a lot on it every year. However, if they buy their own feed production equipment, they can adjust the feed recipe and feed size according to their feeding situation, helping them to breed scientifically and save cost.

According to the form of feed, feeds can be divided into concentrated pellets, feed pellets, floating pellets, etc. To choose which form of feed to decide whether to equip a feed pellet mill or a fish feed pellet mill.

In terms of material, we need to consider what material to use to make livestock feed. Farms usually have more than one type of animal and the recipe varies. Cattle and sheep need roughage and silage, and pigs need concentrated feed. The ingredients of the feed will directly affect the quality of the feed. It is also important to note that if the raw material is too watery, it will not be possible to shape the feed. For these ingredients, we recommend that you dry them first and then make them into pellets.

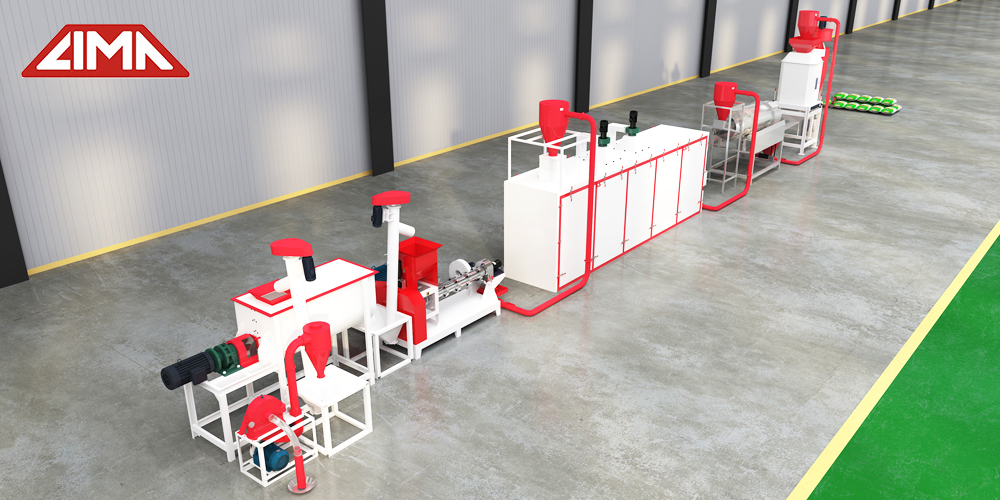

Capacity is an important factor to consider when choosing feed equipment, it will determine the cost and type of equipment. Our production lines are divided into mixed feed lines, pellet lines, and fish feed lines.

Lima fish feed equipment manufacturer can provide you with different guidance for buying biomass pellet equipment and we can customize your own pellet production line according to your requirements. We have years of experience in exporting biomass pellet production equipment, we have completed after-sales service, our engineers can provide you with on-site installation guidance and provide a complete service plan.