Apr 18, 2021 · RICHI Cost of 2 ton per hour capacity poultry feed machine for Ghana market is around 8000USD.. 1. Capacity: 1-2Ton/Hour . 2. With on-site electric control cabinet . 3. Siemens motor, SKF bearing

.jpg)

Apr 18, 2021 · RICHI Cost of 2 ton per hour capacity poultry feed machine for Ghana market is around 8000USD.. 1. Capacity: 1-2Ton/Hour . 2. With on-site electric control cabinet . 3. Siemens motor, SKF bearing

.jpg)

5. Pellets production Process: The feed is then pelletized using flat die feed pellet mill or ring die feed pellet mill which ensures that the material is heavily densified in desirable sizes. 6. Cooling Process: In the end, the feed pellets will be cooled to between 75-85degrees.

.jpg)

The complete small mobile feed pellet production line includes crushing, mixing, granulating, cooling, screening and packaging and conveying equipment. The process flow is complete and reasonable, and the adaptability is strong, which can meet the needs of different users. This product is suitable for processing feed into high-density granules.

Flat die animal feed pellet making machine is for small-scale production of animal and poultry feed pellets, grain feed factory, animal farm, poultry farm. The raw materials are easy to obtain, like corn, maize, wheat bran, rice, and beans. This machine can be powered by electricty or diesel.

.jpg)

How many bags of feed can 100 layers consume? You will require about 6 bags for the first month and an additional 7 to 8 bags for the second month. As it stands in the market, a bag of feed for layers costs between GHS 175.00 – GHS 300.00 in Ghana, however prices are subject to change depending on your location and feeding strategy.

Jan 22, 2021 · The construction of a poultry feed pellet production line plant, regardless of its size and production variety, must be integrated design. The factory plant, equipment, road, pipeline and ancillary equipment are combined to form a complete feed plant which has a reliable supply of raw materials, effective feed production line, power supply, water supply and sales markets, at the same time, has

Oct 17, 2018 · Performance Features of Electric Flat Die Feed Pellet Mill. 1. Driven by electric motor makes it more convenient and environmentally friendly. 2. No need to add extra water to the powder feedstock before pelletizing. 3. To make feed pellets with different diameters, you just need to replace a pellet mill die. 4.

.jpg)

Advantage. Cattle feeding machine made the feed pellet by corn, bean pulp, straw, grass and rice husk. Flat die adopt high quality wear-resisting alloy steel, which are processed by special heat treatment, high hardness, long working life. It is recommended replace roller and die at the same time. We have several diameter for your choice, and

Diesel flat die feed pellet mill can be used to process grain materials into pelleted feed for feeding animals. It is suitable for poultry farms, cattle farms and small scale feed pellet plants etc. This pellet mill can also be used as biomass pellet mill to process biomass materials (wood wastes like sawdust,fish chips and agricultural

.jpg)

Production Output Range: 1~1000,000 tons/year.Lima Machinery supplied poultry and cattle feed plant adopts module design which can realize customized feed processing plant. Meanwhile, as an experienced feed mill machine factory, we can also help you make the best business plan for setting up your own animal feed pellet plant, like mini poultry

The feed pellet mill machine made from KMEC adopts flat die design and has compact structure. So poultry feed mill with flat die is appropriate for home use to make feed pellets. There are two rollers and a die inside the small pellet press. When the machine runs, rollers and die will run to generate great force and high temperature. The great

.jpg)

Poultry Feed. we are leading manufacturer of Poultry Feed Pellet Mill which are manufactured using latest technology. Ensuing their accordance with the defined industry standards, our machines are widely demanded by our customers based all across the world. We offer poultry feed pellet mill. This is being highly appreciated by our clients & is

.jpg)

Nov 18, 2017 · Cape Verde 1-2T/H Poultry Feed Pellet Plant. Date: Aug 31th,2015. Installation cycle: 10 Days. Gambia 1-2T/H poultry Feed Pellet Plant. Date: July 11th,2019. Installation cycle: 10 Days. Tanzania 1-2T/H Chicken Feed Pellet Production Line. Date: Nov 8th,2017. Installation cycle: 15 Days. Rwanda 1-2T/H Poultry Feed Pellet Line. Date: May 8th

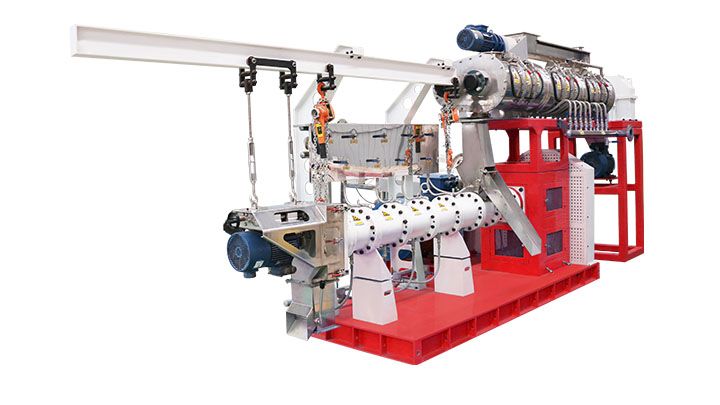

Chicken Bird Duck Pig Poultry Feed Mill Plant This type poultry feed mill plant advantages 1, Ring die pellet model can improve the production capacity. 2, Adopts high accuracy gearbox for high efficiency. 3, Stainless steel conditioner to ensure the high quality of pellet feed. 4, Siemens motor, SKF bearing 5, High output, low noise, compact structure, convenient operation and maintenance.