We devote ourselves to undertaking all poultry feed production line 1-20T/H and to providing more value added service to all the customers. Animal Feed Production Line Poultry / Chicken Feed Production Line

We devote ourselves to undertaking all poultry feed production line 1-20T/H and to providing more value added service to all the customers. Animal Feed Production Line Poultry / Chicken Feed Production Line

.jpg)

Cattle feed mixing machine are used for the mixing of feed ingredients and premixes in feed production plant. The efficient mixing being the key to good feed production.If feed is not mixed properly, ingredients and nutrients will not be properly distributed when it comes time to extrude and pelletize the feed, or if the feed is to be used as mash.

YSKJ150 small homeused animal feed pellet production line / poultry feed pellet machine Shandong Rotex Machinery Co., Ltd. US $875.0-875.0 / Set 1 Set (Min. Order)

Type: SZLP series Small Animal Feed Pellet Mill Capacity(t/h): 0.4-4 Pellet size(mm): 2-12 Application: Can be used for livestock, poultry, ruminants and aquatic pellet feedstuff production.

.jpg)

Dec 18, 2019 · Poultry feed manufacturing process flow chart. The processing of composite poultry feed is usually divided into the following steps: receiving and cleaning of raw materials, crushing of raw materials, batching, mixing, pelleting and packaging. The diameter of the final feed pellets can be 2 to 8 mm. This is a multi-functional feed pellet making

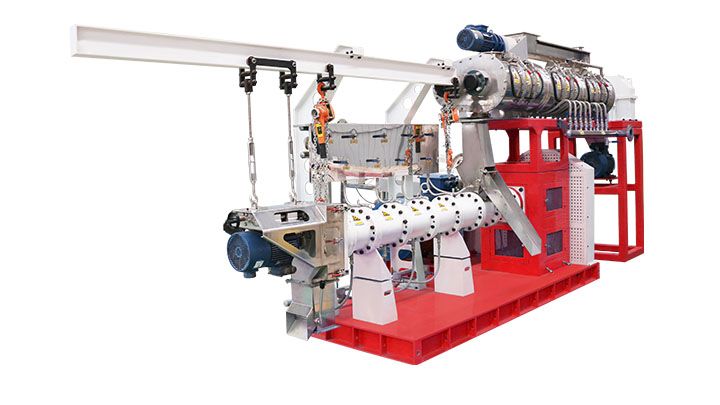

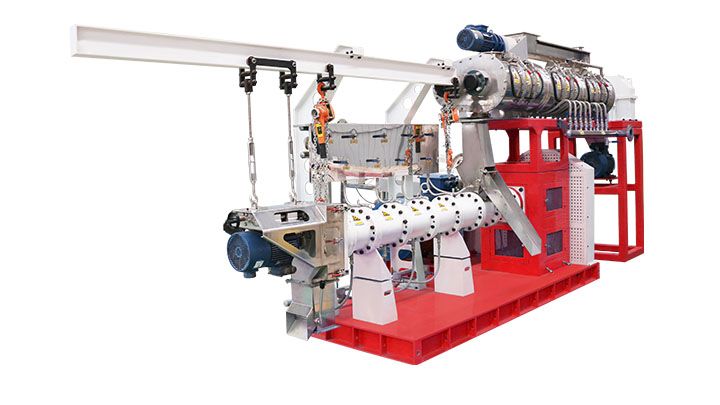

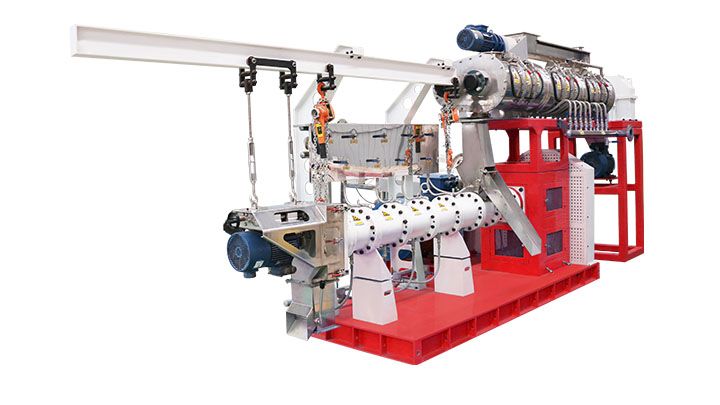

poultry feed production plant for livestock,animal feed processing plant. 1.Animal feed pellet line is a complete set of machines that are specifically used to make feed pellets. 2.The capacity of this poultry feed production plant which can range from 1 ton per hour to 10 tons per hour. 3.Here, you can get specific animal feed pellet plant for

The main processing flow of the poultry feed production line is the raw material receiving and cleaning system, raw material crushing, batching and mixing, pelletizing, cooling, screening, and packaging. This is only a general feed process of 3-4 tons per hour. Different configurations can be customized for different feed types.

The feature of poultry feed production line : 1.Whole line with PLC automatic control; 2. Low price ,high quality,best service 3. Energy saving,304 stainless steel, speed can be adjusted, 4.Can be use for poultry feed pellet,aquatic feed pellet 5. Stable operation,high efficiency,high productivity 5t/hour 6. Pellet diameter from 2mm-12mm

Dec 13, 2021 · Production volume of poultry in France 2020, by species. Published by Statista Research Department , Dec 13, 2021. This statistic presents the estimated volume of the French poultry production in

.jpg)

Commerical Use Automatic Chicken Feed Pellet Production Line 1-2t/h Animal feed pellet mill machine Line 100~1000KG/H 1-18t/h Ring Die Poultry Feed Machine by Electric 60-1000kg/h Flat Die Poultry Feed Machine by Electric/Diesel Engine

diesel engine animal feed machine poultry animal feed feeds processing machines. This STLP300/400 animal feed pellet production line can be used for processing livestock, poultry and aquatic feed pellets, which is specially suitable for medium feed factory, breed farm or aquatic base.

.jpg)

RICHI poultry feed plant can production the 2-12mm duck feed pellet. The biggest capacity is 100t/h, we also can provide the free design , such as the equipment layout , flow chart, pit plan, Installation plan, land plan and 3D drawings. Capacity: 1-100T/H. Main Equipment: Poultry Feed Pellet Machine.

Poultry Feed Production Line Manufacturers, Factory, Suppliers From China, We sincerely do our best to offer the best service for all the clients and businessmen. info@univermachine.com +86-371-60339706

.jpg)

Brand Name: LIMA Weight: 20000 kg Core Components: Engine Pellet diameter: 2-12mm Model Number: 400-600kg/h

Make use of the various poultry feed production line models and sizes by selecting the ones that align with your requirements. Because of their low acquisition costs, the poultry feed production line provide maximum value for money. This is further supplemented by their low operating costs, including readily available spares and affordable cost